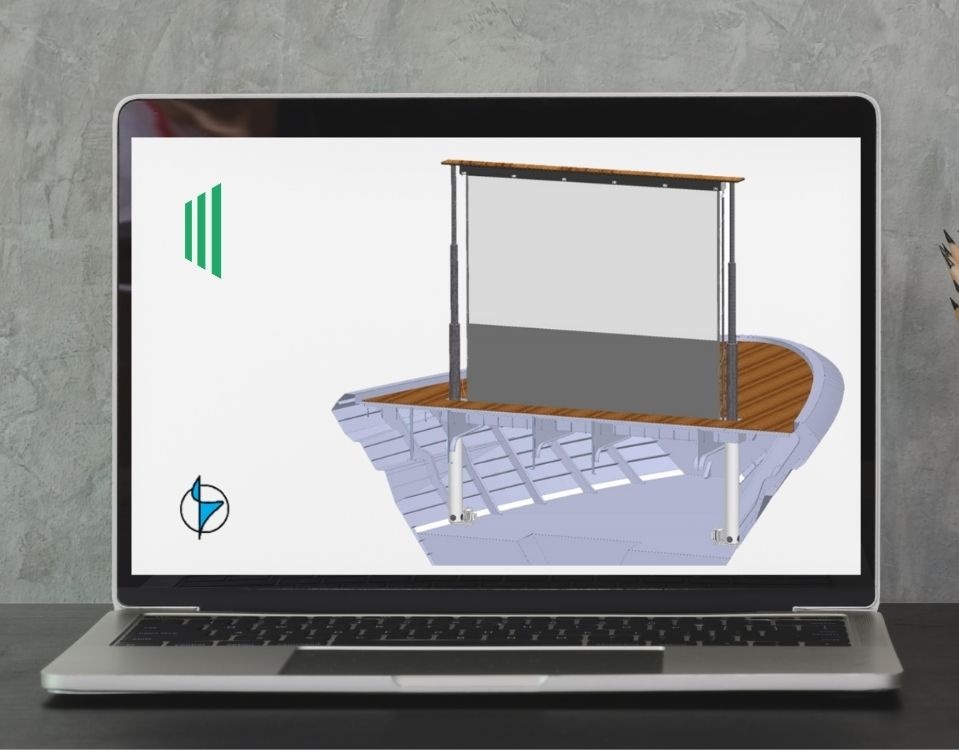

Solico is proud to announce our latest collaboration, providing composite engineering support to Structor Engineering B.V. for the development of a unique 25m2 outdoor cinema screen.

The screen, that has been commissioned for an 80m superyacht that is currently in build, is believed to be the largest screen of its type developed to date, with the highly engineered composite structure providing exceptional image quality on a screen that can be deployed by a single crew member in less than four minutes.

Over the past 20 years, Structor Engineering has built a respected position in the superyacht market, providing a range of composite mast, hinge and lock solutions to some of the most luxurious yachts afloat. Structor’s telescopic carbon fibre composite mast technology, made them the perfect choice to take on this challenging outdoor screen project.

With client specifications calling for a screen that could be rapidly erected by just two crew members, and one that could provide a stable screen image in up to 14 knots of wind, weight reduction, stiffness and confirmation of wind loads were all key design drivers. In coordination with Structor and Solico, a 1:50 scale model of the yacht and screen was tested in the University of Eindhoven’s wind tunnel, delivering extremely reliable design input data for the screen support structure.

Solico supported Structor throughout the eight-month project and provided structural verification and laminate details for the carbon parts including the telescopic tubes, top member, side tubes and bottom member of the supporting structure for the cinema screen. These components were all produced by Structor’s sub-contractors, with Solico also coordinating design details between the frame components and the screen membrane itself.

In March 2021, a pre-installation test and sign-off was successfully completed, with the composite structure raised and the textile membrane tensioned to a perfect wrinkle free projection screen by one person in less than four minutes. The screen components are now going through the final finishing processes with the complete assembly planned to be installed on the superyacht in the next few months.

“We fully appreciated Solico’s breadth of knowledge and expertise for a challenging project like this. Having engineered and validated the composite structures, they were also invaluable in coordinating other technical details, reviewing the wind tunnel testing and membrane calculations” comments Bouwe B. Speerstra, Structor Engineering BV.

ALL BENEFITS OF COMPOSITE

Do you have a similar challenge? Please don't hesitate to contact us for a no-obligation consult. Give us a call +31 162 46 22 80 or complete the contact form and Coen Meerbach will contact you a.s.a.p.

CONTACT US