Flynt founder Robert-Jan Sanders has done the impossible; he has realized his dream to build the ultimate sport boat: elegant without any compromise to performance. “I asked myself: what if I were to build a boat that accumulates everything I’ve learned, and done, and missed in over 20 years in the boating business? People would say I was mad.” Many did initially, but he has proven them all wrong because the Flynt 956 Nova is everything everyone ever wished for in a sport boat. An instant icon; No compromises, only fun.

Why Flynt?

Flynt owes its distinctive character to founder Robert-Jan Sanders. He established the brand as the crown to his yearlong experience in the motor yacht business. "A lot of sport boats look alike," Robert-Jan explains, "My design was based on practical usability. The same goes for the layout. After that, a modern design has been added to the boat. Boat architect Vripack converted the idea into a distinctive, luxurious design. You cannot find a similar sport boat in the world. Beautiful technique combined with and a high-end layout. “It’s iconic", according to a proud Robert-Jan.

Flynt and Solico

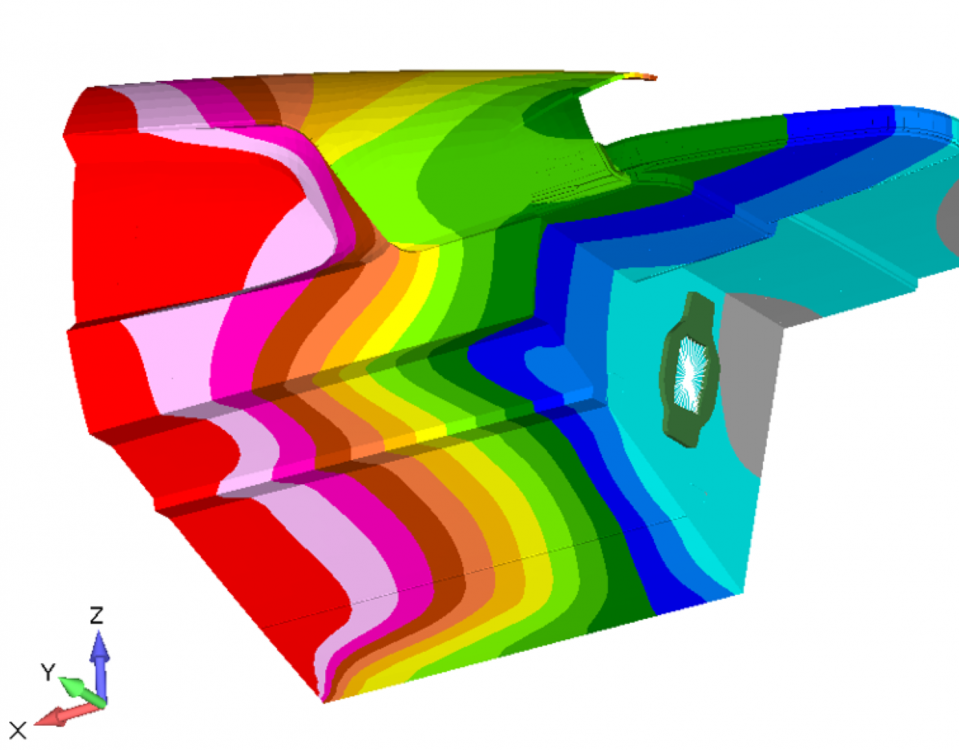

Robert-Jan aims to beat the standard in the luxury segment with the best available price-quality ratio. His objective was crystal clear: to develop a cost-efficient, high-quality, high-end sport boat, to be able to reach a top speed of over 50 knots whilst meeting ISO 12215-5 regulations (concerning the calculation of sport boats). He reached out to Solico, because we could provide him with the material to meet his needs. Composite, with its freedom of shape, combined with good structural properties and low weight makes for the ideal material to build a high-performance sport boat. "Solico struck me as a very professional agency, that made me feel confident about the collaboration," says Robert-Jan. "They listened very carefully to my story and helped me made my dream come true. Little information was available at the start of this project. It was a challenge to translate all wishes and needs into good constructive solutions.” "For Solico, the unique design was a difficult one to calculate," explains Robert-Jan. "The unique design made it challenging to apply the good shape properties and weight calculations. They solved this very well". Solico also took an advisory role throughout the whole process and advised to seek assistance from Vripack, a well-known sports boat architect with whom Solico had worked with before. It was also up to Solico to determine a laminate plan and the construction for the boat based on a scale model.

Review of the client: how do you feel about working with Solico?

Robert-Jan answers: “Very well. The project was challenging and Solico remained professional under all circumstances, they showed great understanding. I experienced the cooperation as very rewarding. We assume that they understand the tricks of the trade and that the product remains intact after 5 years. I'm very satisfied about working with Solico and asked them to collaborate in future projects as well”.

The first Flynt crafts were sold before they even came on the market. Want to know more? Check the website via www.flyntyachts.com

Why are composites used here?

Lightweight

Applying composites leads to significant weight savings compared to a metal structure. This improves the stability and overall performance.

Freedom of geometry

Double curved shapes are easily produced in composite materials at almost no extra cost. For production of limited series the relatively low moulding costs are an additional benefit.

ALL BENEFITS OF COMPOSITE

Need some help with engineering? Our engineers love a challenge! Don't hesitate to contact us for a no-obligation consult. Give us a call +31 162 46 22 80 or complete the contact form and Coen Meerbach will contact you a.s.a.p.

CONTACT US